Livermore materials scientists, physicists, and engineers have earned an international reputation for developing advanced manufacturing processes that produce materials and components on an accelerated schedule, at reduced cost, and often possessing properties impossible to obtain with traditional manufacturing techniques. Examples include high-performance optics, biocompatible devices, advanced battery components, and radiation detection materials.

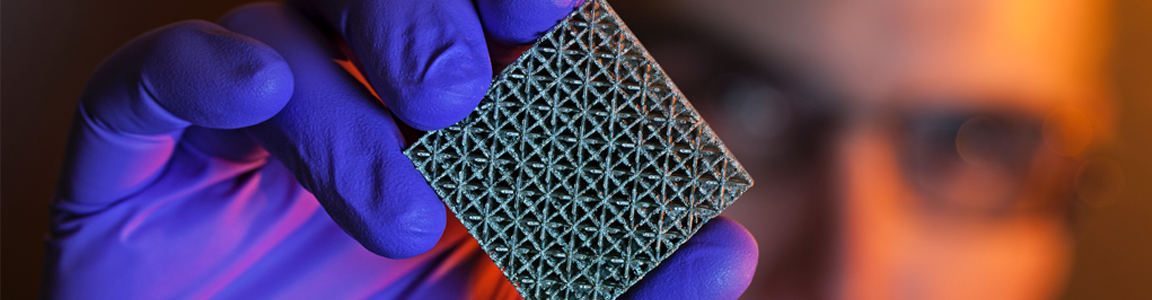

A key focus is additive manufacturing (AM), which is transforming manufacturing by producing materials with new structural, thermal, electrical, chemical, and photonic properties. AM, sometimes called 3D printing, uses successive layers of material (polymers, metals, and ceramics) to precisely fabricate 3D objects. Livermore’s approach integrates manufacturing expertise, precision engineering, materials science, and high-performance computing to produce innovative materials for stockpile stewardship, global security, and energy security.

AM technologies are revolutionizing the design-build-test cycle. A designer often can produce a prototype part in a few hours, immediately assess its viability, and if necessary change a design for improved performance. Finished and validated components can be produced in weeks to months instead of several years using conventional manufacturing approaches.